Pouch Filler, Actionpac, Model APR360P-28, Combination Scale, Model Multi109 #4489768

Pouch Filler, Actionpac, Model APR360P-28, Combination Scale, Model Multi109 #4489768

Location:California

Available quantity:1

Description

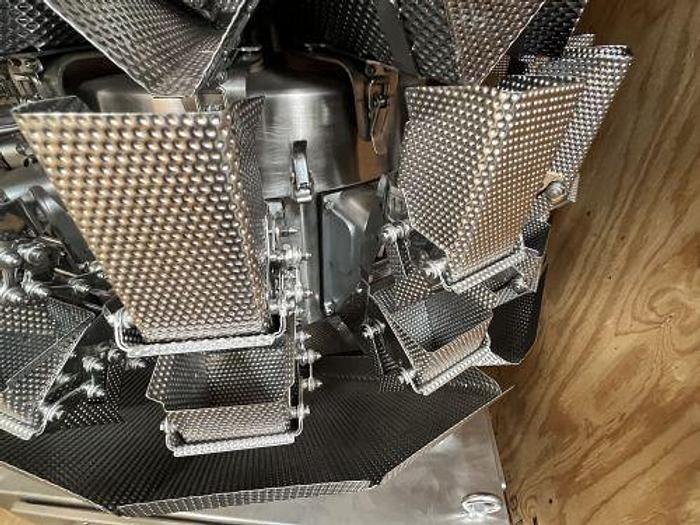

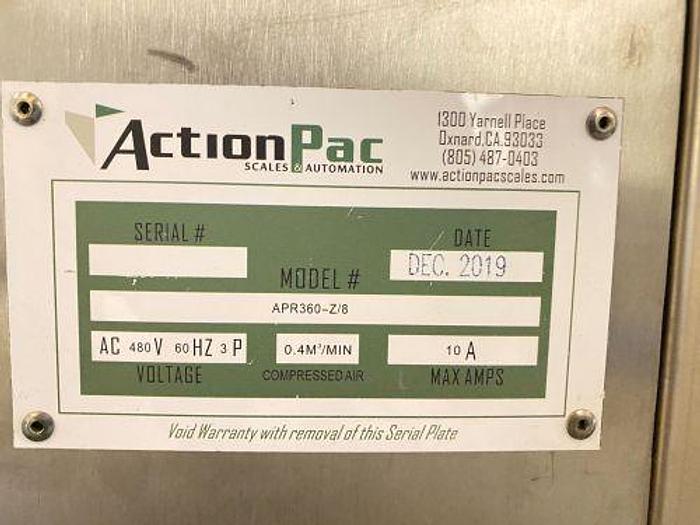

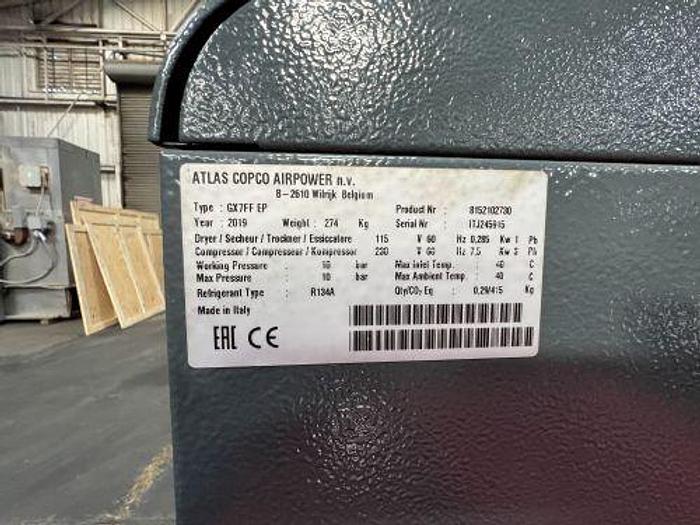

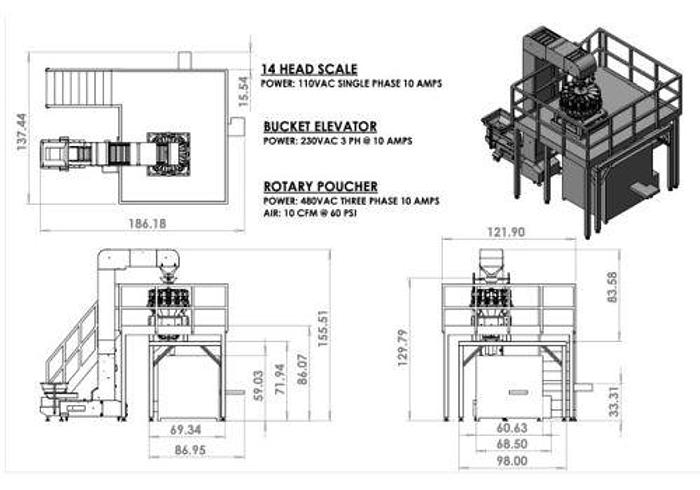

ActionPac Scales stand-up pouch packing line, including Actionpac Multi109 14-head combination scale with MINI109CLX2 2-Lane scale, bucket elevator, APR360P-28 Rotary poucher, Checkweigher, mezzanine, air compressor. Can handle 30+ bags per minute (1200+ bags per hour), depending on factors like product flow, bag material, and head space. It features a convenient master adjust mechanism for easy bag size changeover, and some units include a Zipper Ripper for opening closed zipper pouches, increasing speed. The equipment is equipped with a Meenjet MX1 inkjet date coder. Constructed with 304 stainless steel food contact surfaces and a carbon steel structure with epoxy coating, it packs bags within the dimensions of 100mm-200mm width and 100mm-300mm length. It has heavy-duty leveling feet, UL-compliant cables and parts, a Siemens PLC and touchscreen, embedded transformer, Omron thermal controller, Orion vacuum pump, SMC pneumatics, and supports nitrogen flush. The power requirement is 480VAC-5 wire (3-phase) @ 20A +-10% 50/60Hz, with an air consumption of 10-12 CFM.

Specifications

| Stock Number | 4489768 |

| Manufacturer | ActionPac |

| Model | APR360P-28 |

General Information

Manufacturer details - This fully automated system is designed to efficiently pack various products into stand-up (ziploc) pouches. Offers accuracy, ensuring precise weighing and filling of bags with an accuracy of 0.5 grams. With a packing speed of up to 40 bags per minute, it efficiently handles different bag sizes and materials. The line includes a digital date coder, allowing for convenient printing of best by dates, batch numbers, and other essential information. Suitable for snacks, tea, coffee, pet treats, and non-food items. Compatible with various pre-made bag types, such as zipper pouches and flat pouches, providing flexibility for packaging needs.