Evaporator, WFI Still, Vapor Compression, MECO, 750 GPH, #5991234

Evaporator, WFI Still, Vapor Compression, MECO, 750 GPH, #5991234

Location:Brisbane, CA

Available quantity:1

Description

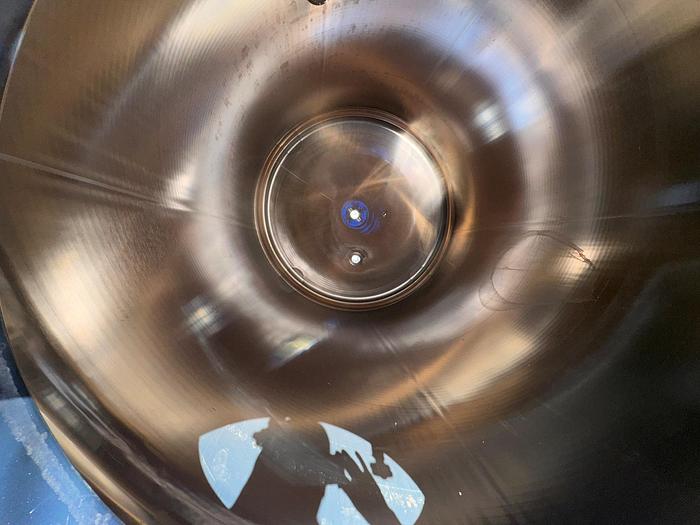

MECO Vapor Compression Still, model PES750MSSH, serial number 10118, uses deionized or softened feedwater to produce high-quality distilled water through a continuous distillation process, designed to produce 750 gallons per hour (GPH) of Water for Injection (WFI). The system operates by boiling feedwater in a vertical shell-and-tube heat exchanger (evaporator), where steam is generated, compressed, and condensed into distilled water. Key components include a demister for steam purification, a vapor compressor, sanitary heat exchangers constructed with 316L stainless steel, and an insulated, vertical 10,000 liter stainless steel WFI storage tank. The unit is skid-mounted with PLC controls for automated operation and features integrated piping for feedwater, distillate, and blowdown management.

New in 2021 and used for less than one year.

MECO WFI system includes a pretreatment filtration system featuring a multimedia filter, carbon filter, and dual-stage water softeners to remove particulates, chlorine, and hardness minerals. Additionally, it is equipped with a sanitization process.

Specifications

| Stock Number | 5991234 |

| Manufacturer | MECO |

| Model | PES750MSSH |

| Year | 2021 |

| Serial Number | 10118 |

| Capacity | 750 Gallons/Hour |

| Materials of Construction | 316L Stainless Steel |

| Control System | Allen-Bradley Compact Logix PLC |

| Operation Modes | Out of Service, Warm-up, Hot Standby, Normal Operation |

| Energy Efficiency | Heat Recovery and Adjustable Compressor Speeds |

| Basis | FOB |

Additional Information

Functional Specifications - The MECO Vapor Compression Still (Model PES750MSSH, Serial #10118) is designed to produce 750 gallons per hour (gph) of Water for Injection (WFI) using deionized or softened feedwater. The system operates via PLC-controlled vapor compression distillation for continuous and automated operation. The unit is skid-mounted, pre-piped, and pre-wired, requiring only utility and piping connections for installation.

Key operation modes include Out of Service, Warm-up, Hot Standby, and Normal Operation, with both manual and remote operation options. The PLC manages critical processes such as feedwater level, distillate level, evaporator pressure, and distillate temperature through PID control loops. Distillate is directed to storage or waste based on quality parameters, with alarms and safeguards ensuring operational integrity.

Energy efficiency is achieved through adjustable compressor speeds and integrated heat recovery systems. The system’s design supports minimal operator interaction while maintaining compliance with USP standards for WFI quality. Regular maintenance, including descaling, ensures optimal performance and consistent output.